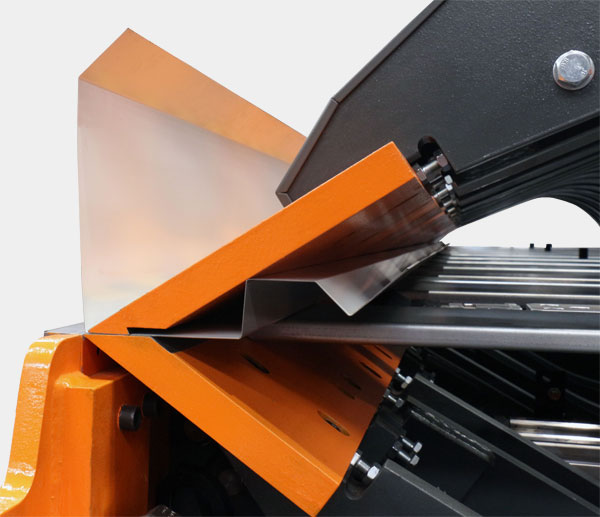

Space for every kind of work. With their deep pit inside and their large inclination of the tools you will be able create new varieties on profile construction.

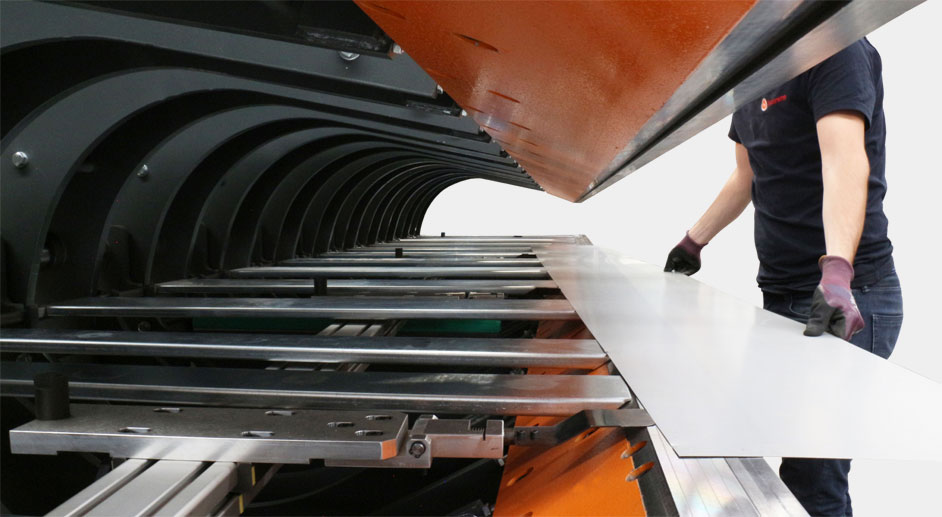

The rounded “C” arms are designed to assure enough pressure for a perfect hemming.

A maximum 145 degrees of rotation on their strong linkages.

It doesn’t seem bended. Small radius on thin materials results on beautiful profile.

With a large range of position, between 5mm and 1100mm, you always have a reliable support. Precise ball screw for the 0,02 mm of tolerance on servo – motorized backgauge.

Tappered backgauge that will work on both extremities of the machine within a maximum difference of 450mm.

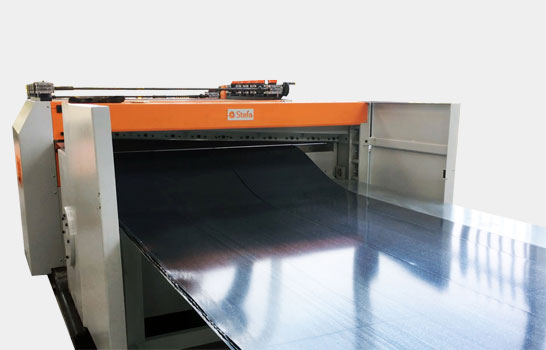

The shear can run smoothly on different materials. Its carriers on two linear guides attached on bending beam for you are not engaged in cutting operations.

ProBender

The standard software that can offer your daily needs in a simple way. The axes are automatic, and the controller is equipped with a modern touch screen of 10”.

Some features:

- Bending Beam, Clamping Beam and Backgauge have position feedback.

- Automatic position of Backgauge.

- Hydraulic radius/thickness adjustment.

- Memory for 50 programs with 20 steps.

- Cut operation.

- Automatic Hemming.

- Hold to run mode movement.

EliteBender CNC

EliteBender CNC, the advanced graphical software with the last technology of sheet metal working.

- Draw the profile with a finger.

- Automatic development calculous for all thickness.

- Database for angle corrections and materials.

- Solid State Disk with capacity for 600.000 programs.

- Pressure Sensor, High-speed Servo-motorized and Conical Back gauge and proportional control for hydraulic circuit.

- Industrial PC with monitor touch 21”. Able to have remote support with ethernet connection.

- Elite 4.0: Send programs from office to the machine! *

- Another many features.

On the Folding Machine Stefa VH protective measures are taken seriously when concerns on design and construction of the equipment.

These are some protective measures that are installed on the machine to ensure the safety and health requirements of European harmonized standard:

- Safety pedals switch.

- Red emergency rope.

- Hydraulic and electric redundancy.

- Intermediate Stop and safety speed.

- Laser beams for clamping and shear.

The Stefa Folding Machine do a lot of the work but will be more productive if have the right company.

- Support table with manual transversal cut and manual Decoilers

The Stefa Folding Machine do a lot of the work but will be more productive if have the right company.

- Automatic feeder with slitting and straightener rolls.

suitable model

VH412

Technical Features:

VH412

Technical Features:

VH412

Technical Features:

VH415

Technical Features:

VH415

Technical Features:

VH415

Technical Features:

VH420

Technical Features:

VH420

Technical Features:

VH420

Technical Features:

VH430

Technical Features:

VH430

Technical Features:

VH430

Technical Features:

VH612

Technical Features:

VH612

Technical Features:

VH612

Technical Features:

VH615

Technical Features:

VH615

Technical Features:

VH615

Technical Features:

VH620

Technical Features:

VH620

Technical Features:

VH620

Technical Features:

VH630

Technical Features:

VH630

Technical Features:

VH630

Technical Features:

VH812

Technical Features:

VH812

Technical Features:

VH812

Technical Features:

VH815

Technical Features:

VH815

Technical Features:

VH815

Technical Features:

VH820

Technical Features:

VH820

Technical Features:

VH820

Technical Features:

VH830

Technical Features:

VH830

Technical Features:

VH830

Technical Features:

VH1012

Technical Features:

VH1012

Technical Features:

VH1012

Technical Features:

VH1015

Technical Features:

VH1015

Technical Features:

VH1015

Technical Features:

VH1020

Technical Features:

VH1020

Technical Features:

VH1020

Technical Features:

VH1030

Technical Features:

VH1030

Technical Features:

VH1030

Technical Features:

VH1215

Technical Features:

VH1215

Technical Features:

VH1215

Technical Features:

VH1220

Technical Features:

VH1220

Technical Features:

VH1220

Technical Features:

VH1230

Technical Features:

VH1230

Technical Features: